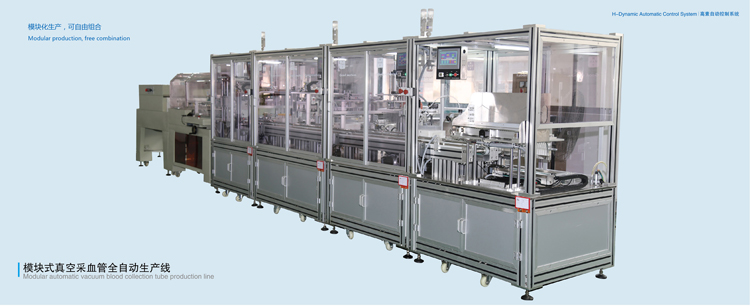

Modular Production Line

Modular Production Line

Brief Introduction & Advantages:

The whole production line connected by individual modular,include labeling,tube loading,gel filling(optional).dosing,drying,stoppering & capping,vacuuming,tray loading,shrink packing and etc.Improve traditional process with gel filled online,ensure the whole running smoothly with free modular combination.Each modular controlled by its own PLC,3 skilled workers watched the whole line to reach 15000~18000pcs/h capacity.No human operation online that decrease error caused by human or difference between batches,plus auto inspection during all the line process,which improve production efficiency and products quality.

Main Technical Parameters:

1.Tube size:diameter 13mm (length 75mm or 100mm),diameter 16mm(length 100mm)

2.Stopper&cap:according to the sample provide standard size

3.Production capacity:15,000~18,000 pcs/hour

4.Atomazation dosing volume:error≤1%,10ul/time,20ul/time,30ul/time,40ul/time,200ul/time,300ul/time,400ul/time,500ul/time,600ul/time

5.Stoppering & capping pass rate :≥99%

6.Vacuuming stopper-cap pass rate :≥99%

7.Power supply:380V/50HZ Power:12KW

8.Air consumption:clean compressed air pressure:0.6~0.8Mpa,clean compressed air consumption:300m3/min

9.Dimensions:3.1*1.3*2.4m(L*M*H)

10.Weight:2T

11.Configuration:

Vacuum pump:LEYBOLD(Germany);

Pneumatic:AirTAC or SMC pneumatic cylinders,solennoid valves,and etc.,ensure stable operation,long life operation;

Electrical appliance:Schneider(Germany)electric elements,Omron (Japan)detector,AB (U.S.)or Panasonic(japan)motor,Mitsubishi(Japan)PLC/HMI;

Main pars:all material steel,stable and reliable and easy to clean.High efficient filtration devices with optimal layout design with optimal layout design to gurantee Class A online,compny with GMP requirement.